Since the announcement in 2010 June, TMT-India has made significant progress in identifying the systems to be developed in the country for the TMT project and the processes that are involved in realizing them as part of India’s in-kind contribution to the project. TMT-India is currently working on Technology Demonstration and Prototyping of components related to the primary mirror segments and control systems.

Hardware

Edge Sensors:

Edge sensors are an important component of the TMT. They measure the relative displacement, tip and tilt of the segments. Each segmented mirror will have 12 edge sensors and in total 3,234 sensors for entire M1. The work to produce 25 prototype sensors has already been initiated by TMT-India at General Optics Asia Limited (GOAL) Puducherry.

Actuators:

In order to achieve very high spatial resolution as well as sensitivity, all the 492 hexagonal mirror segments of the TMT must be precisely positioned with respect to each other to form a 30-meter hyperboloid primary mirror. The M1 control system (M1CS) performs this task, with the help of actuators that correct for the segments’ tip-tilt and piston errors measured by edge sensors. Each mirror segment will be driven by three actuators and altogether 1,476 actuators are required to keep all the segments aligned. 10 such prototype actuators are under manufacture at Avasarala Technologies Limited (ATL), Bangalore.

Segment Support Assemblies (SSAs): Each mirror segment will be mounted on a Segment Support Assembly (SSA). Each SSA is tuned for a specific type of segment, so there will be 82 types of SSAs. Each mirror segment requires an SSA that has several subcomponents that are to be manufactured separately and integrated.

A group of engineers and scientists from TMT-India are interacting closely with Indian industries and Mark Sirota (TMT Telescope Controls Group Leader) in the prototype development of the above components.

Segment polishing:

Providing primary mirror segments to the TMT is one of the major goals of India-TMT. As a first step towards this, India has to demonstrate segment polishing capability either using Stress Mirror Polishing (SMP) technique or CNC approach.

Software:

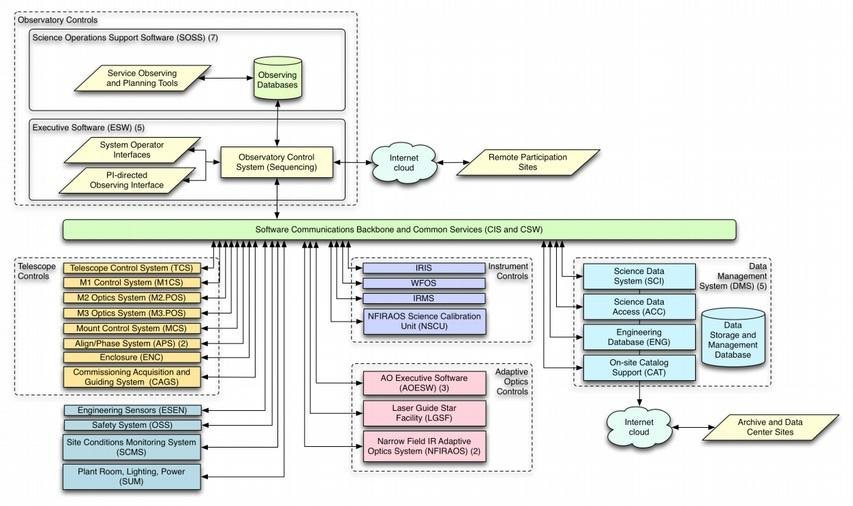

The TMT observatory control software consists of a set of software components that control the operations of the telescope, the mirrors, the telescope dome or enclosure, and the various instruments. India is responsible for the Observatory Software (OSW), Telescope Control Software(TCS) and Generation of Infrared Guide Star Catalog.

Observatory Software

The Observatory software (OSW) supports and implements the operations/observing workflow of a telescope. India-TMT is responsible to deliver and maintain the end-to-end observing software system for TMT. Main components of TMT-OSW are

- Common Software (CSW),

- Executive Software (ESW),

- Data Management System (DMS),

- Science Operations Support System (SOSS).

Each component has multiple sub-components, leading to a total of approximately 30 India-TMT Work Packages (WPs) under TMT-OSW.

Role of ITCC in OSW

- ITCC is responsible to deliver and maintain the end-to-end observing software system for TMT.

- A vendor (ThoughtWorks Pvt Ltd) is developing these modules through a contract with ITCC.

- Software Engineers at ITCC do the testing and quality assurance of the developed software, it was later validated and approved by TMT project.

- The effort estimation, monitoring of progress and delivery are managed by ITCC.

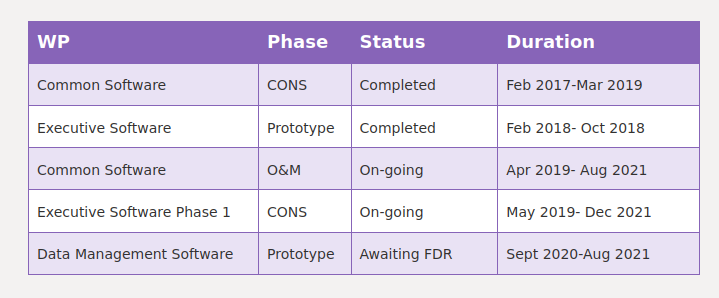

India TMT with vendor M/s Thoughtworks Private Limited has contributed to the following modules till now.

Programming Language and Technologies used

- Scala and Java

- Akka Framework

- Javascript

- React Framework

- Antd Designs

GitHub Repository of the OSW developed code is TMT Software

Telescope Control Software

Generation of Infrared Guide Star Catalog

TMT instruments operating in the infrared wavelength regime will be supported with AO system. In addition to the laser guide stars, the observations with AO system also require natural guide stars. A catalog of guide stars with their parameters to the required accuracy should be available before the operation of TMT begins. Currently such a catalog in infrared does not exist. Institutes in India are involved in the generation of this catalog. The initial phase of this process is completed and the next phase has started.